-

AMR

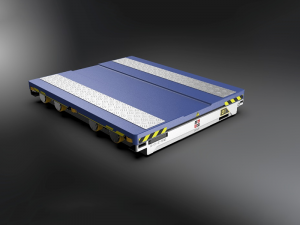

AMR trolley, imotokari yekutakura ine otomatiki ekutungamira maturusi akadai semagetsi emagetsi kana optical, anogona kufamba nenzira yakatemerwa inotungamira, ine kuchengetedza kuchengetedza uye akasiyana mabasa ekutamisa. Mukushanda kwemaindasitiri, imotokari yekutakura isingade mutyairi. Simba rayo rinobva bhatiri rechargeable.

Yakanyura AMR: nyura muzasi merori, uye otomatiki kukwira uye kupatsanura kuti uone kuburitsa zvinhu uye kudzokorodza mashandiro. Zvichienderana neakasiyana ekumisikidza uye tekinoroji tekinoroji, otomatiki mota dzekutakura dzisingadi kutyaira kwevanhu dzinonzi pamwe chete AMR.

-

Palletizer

Iyo palletizer chigadzirwa cheiyo organic musanganiswa wemakina uye zvirongwa zvekombuta, Inovandudza kugona kwekugadzirwa kwemazuva ano. Palletizing michina inoshandiswa zvakanyanya muindastiri yepalletizing. Palletizing marobhoti anogona kuchengetedza zvakanyanya mutengo wevashandi uye nzvimbo yepasi.

Iyo palletizing robhoti inochinjika, chaiyo, inokurumidza, inoshanda, yakagadzikana uye inoshanda.

Iyo palletizing robhoti sisitimu inoshandisa yakarongeka robhoti mudziyo, iyo ine zvakanakira zvediki tsoka uye vhoriyamu diki. Pfungwa yekumisikidza inoshanda, inoshanda uye inochengetedza simba yakazara otomatiki block muchina mutsara wegungano inogona kuitika.

-

Tray kupeta muchina

Tray kupeta muchina ndeye otomatiki midziyo, iyo inonzi zvakare kodhi tray muchina, inoshandiswa mutireyi yekufambisa sisitimu, yakasanganiswa neakasiyana maconveyor, kugovera matireyi asina chinhu kumutsetse wekutakura. Muchina wekupeta tireyi unoshandiswa kurongedza mapallets ega muma pallets akaturikidzana, anosanganisira: pallet stacking inotsigira chimiro, pallet yekusimudza tafura, mutoro sensor, pallet chinzvimbo chekuona, kuvhurika / kuvhara robhoti sensor, kusimudza, kudzika, chepakati chinzvimbo switch.

-

RGV

RGV inomirira Rail Guide Vehicle, inonziwo trolley. RGV inoshandiswa mumatura ane nzira dzakasiyana-siyana dzepamusoro-density yekuchengetedza, uye nzira dzinogona kugadzirwa maererano nehurefu hupi hupi hunowedzera simba rekuchengetedza reimba yose. Mukuwedzera, paunenge uchishanda, iwe unogona zvakare kutora mukana wekuti forklift haidi kupinda munzira, yakasanganiswa nekukurumidza kufamba kwetrolley munzira, inogona kunyatso kuvandudza kushanda kweiyo dura uye kuita kuti ive yakachengeteka.

-

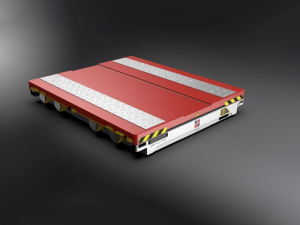

4D shuttle masisitimu yakajairika mhando

Semidziyo yepakati yenzira ina yemotokari yakangwara yakadzika warehouse, iyo yakatwasuka uye yakachinjika mota inonyanya kuve ine rack kusangana, yemagetsi system, magetsi system, drive system, jacking system, sensor system, nezvimwe.

-

4D shuttle masisitimu kune yakaderera tembiricha

Chimiro chepasi-tembiricha vhezheni yecrossbar inonyanya kufanana neyeiyo standard version. Musiyano mukuru uri munzvimbo dzakasiyana dzekushanda. Iyo yakadzika-tembiricha vhezheni yemuchinjiko inonyanya kushandiswa munharaunda ye - 30 ℃, saka kusarudzwa kwayo kwemukati kwakasiyana zvakanyanya. Zvese zvemukati zvemukati zvine yakaderera tembiricha kuramba, bhatiri zvakare yakaderera-yepamusoro-inoshanda bhatiri, iyo inogona kutsigira kuchaja munzvimbo -30 °C. Uye zvakare, iyo yemukati yekudzora sisitimu yakavharwa zvakare kudzivirira condensation mvura kana kuchengetedza kuri kunze kwedura.

-

4D shuttle masisitimu ekumhanyisa application

Iyo meshini yeiyo yepamusoro-yekumhanya vhezheni yemotokari yakatwasuka uye yakachinjika yakangofanana neyeyakajairwa yakatwasuka uye yakachinjika mota, musiyano mukuru uri mukuvandudza kwekumhanya kwekufamba. Tichifunga nezve yakajairika uye yakagadzika pallet zvinhu, kuitira kuti uvandudze kushanda kwese kweprojekiti uye kuderedza huwandu hwemachinjiro anoshandiswa, yakakwira-kumhanya vhezheni yemuchinjiko inotsanangurwa. Iyo yekufamba yekumhanyisa index yakapetwa kaviri iyo yeyakajairwa vhezheni, uye iyo jacking kasi inoramba isina kuchinjika. Kuti uvandudze kuchengetedzeka, laser yekuchengetedza yakashongedzerwa pamidziyo kudzivirira njodzi kubva pakumhanya-mhanya.

-

4D shuttle masisitimu einorema mutoro application

Iyo michina yeheavy-duty crossbar yakangofanana neyeiyo yakajairwa vhezheni, mutsauko mukuru ndewekuti mutoro wayo wekutakura unovandudzwa zvakanyanya. Hutakuri hwayo hunosvika zvakapetwa kaviri kune iyo yakajairwa vhezheni, uye zvimwechetezvo, kumhanya kwayo kunoenderana nekumhanya kunodererawo. Zvose kufamba uye kumhanya kwejacking kunoderera.

-

Dense Racking ye4D shuttles

Iyo ina-nzira yakadzika yekuchengetera sherufu inonyanya kuumbwa rack zvimedu, Sub-channel crossbeams, Sub-channel tracks, horizontal tie tsvimbo zvishandiso, Main chiteshi crossbeams, Main chiteshi tracks, Kubatanidza racks nevhu, zvinogadziriswa tsoka, kumashure kudhonza, mambure ekudzivirira, manera ekugadzirisa, Chinhu chikuru chesherufu uye Q53 zvinhu zvesherufu uye Q53 zvinhu Wuhan Iron uye Simbi inosarudzwa uye inoumbwa nekutonhora kutenderedza.

-

High speed hoisting system

Iyo inodzosera pallet elevator inonyanya kuumbwa nezvikamu zvikuru senge mudziyo wekutyaira, chikuva chekusimudza, counterweight balance block, yekunze furemu, uye yekunze mesh.

-

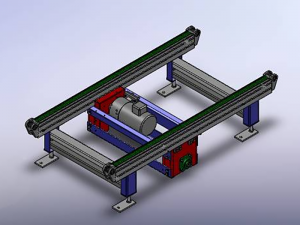

Ruzivo 4D shuttle conveyor system

Iyo mota inotyaira shaft yekutyaira kuburikidza neboka rekutapurirana, uye dhiraivha shaft inotyaira cheni yekufambisa kuti ione basa rekufambisa repallet.

-

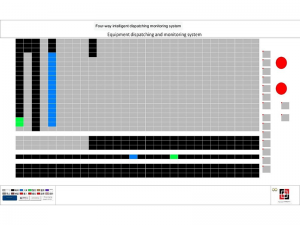

WCS-Warehouse Control System

Iyo WCS system ine basa rekuronga pakati peiyo system nemidziyo, uye inotumira mirairo yakapihwa neWMS system kune yega yega yekushandisa yakarongeka. Pane kuenderera mberi kutaurirana pakati pemidziyo neWCS system. Kana iyo michina yapedza basa, iyo WCS system inozviitira kutumira data neWMS system.