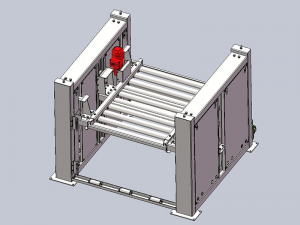

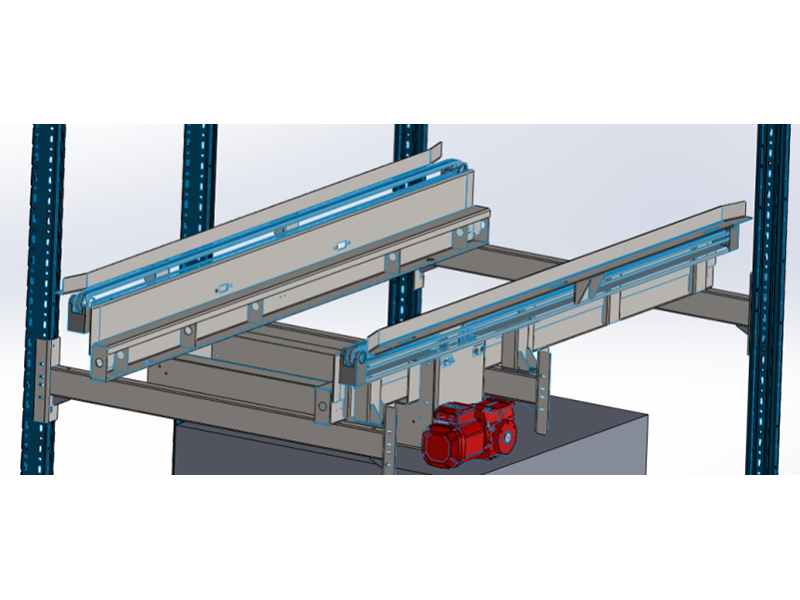

Ruzivo 4D shuttle conveyor system

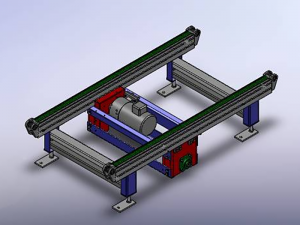

cheni conveyor

| project | Basic data | Remark |

| model | SX-LTJ-1.0T -600H | |

| Motor reducer | SEW | |

| chimiro mhando | Iyo furemu inogadzirwa nealuminium alloy, uye makumbo nemabhenji anogadzirwa nekabhoni simbi | |

| control method | Manual/stand-alone/online/automatic control | |

| kuchengetedza matanho | Kupindirana kwemagetsi, madhiraivha ekudzivirira pamativi ese | |

| tora mwero | JB/T7013-93 | |

| payload | Max 1000KG | |

| kuongorora kutakura zvinhu | Photoelectric Sensors | Murwere/P+F |

| chain track | Low friction naironi track | |

| conveyor cheni | Donghua Chain | |

| kubereka | Fukuyama Hardware, Yakavharwa Bhora Bearings | |

| kufambisa kumhanya | 12m/min | |

| Surface Kurapa uye Coating | Pickling, phosphating, kumwaya | |

| noise control | ≤73db | |

| kupfeka kwepamusoro | komputa grey | Akabatanidzwa swatches |

Equipment structure

Iyo conveyor inoumbwa nefuremu, outriggers, drive unit uye zvichingodaro. Iyo furemu yakagadzirwa nealuminium alloy, uye migumo yese yakagadziriswa isina mazino ekudzosera mavhiri. Iyo cheni yekutakura yakatwasuka kaviri-mutsara cheni ine pitch P = 15.875mm. Rutsigiro rwecheni rwakagadzirwa neakakwira molecular polyethylene (UHMW) ine self-lubricating maitiro. Iwo welded outriggers akabatana neiyo huru furemu nebhaudhi pressure plate, iyo M20 screw tsoka dzekugadzirisa dzakabatana nevhu, uye kureba kwenzvimbo inotakura inogona kugadziriswa ne +25mm. Chishandiso chekutyaira chinoumbwa neakavakirwa-mukati deceleration mota pakati, dhiraivha shaft gungano, yekutapurirana sprocket seti, chigaro chemota uye cheni tensioning mudziyo, uye screw-mhando inogadzirisa tensioner pulley tension ketani inotakura.

kushanda musimboti:

Iyo mota inotyaira shaft yekutyaira kuburikidza neboka rekutapurirana, uye dhiraivha shaft inotyaira cheni yekufambisa kuti ione basa rekufambisa repallet.

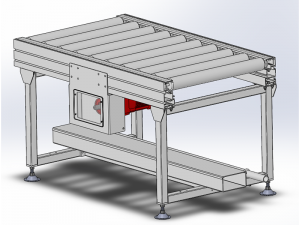

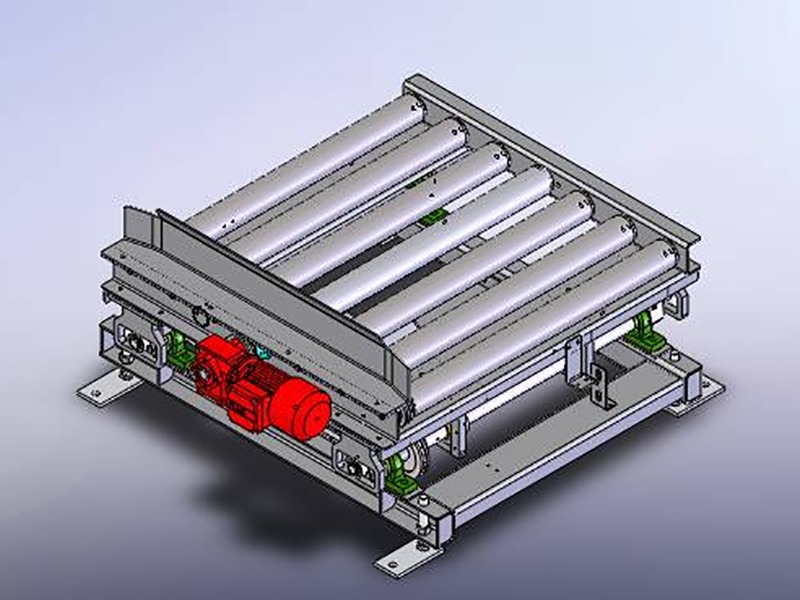

Roller conveyor

| Item | Basic data | Mashoko |

| Model | SX-GTJ-1.0T -600H | simbi yakagadzirwa |

| Motor reducer | SEW | |

| chimiro mhando | carbon steel bending | |

| control method | Manual/stand-alone/online/automatic control | |

| payload | Max 1000KG | |

| kufambisa kumhanya | 12m/min | |

| roller | 76 kaviri cheni roller | |

| drive cheni | Huadong Chain Factory | |

| kubereka | Ha axis | |

| Surface Kurapa uye Coating | Pickling, phosphating, kumwaya | |

Equipment structure

Equipment chimiro: The roller table machine inoumbwa nefuremu, outriggers, rollers, drives and other units. Roller φ76x3 single side double sprocket galvanized roller, roller spacing P=174.5mm, single side double sprocket. Iwo welded outriggers akabatana neiyo huru furemu nebhaudhi pressure plate, iyo M20 screw tsoka dzekugadzirisa dzakabatana nevhu, uye kureba kwenzvimbo inotakura inogona kugadziriswa ne +25mm. Chishandiso chekutyaira chinoumbwa neyakavakirwa-mukati deceleration mota iri pakati, yekutapurirana sprocket seti, chigaro chemota uye cheni tensioning mudziyo.

Kushanda musimboti: Motokari inotyaira roller kuburikidza neketani, uye roller inotumirwa kune iri padyo roller kuburikidza neimwe cheni, uyezve kune imwe roller kuona basa rekufambisa remutakuri.

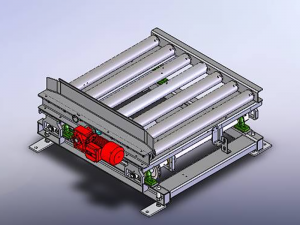

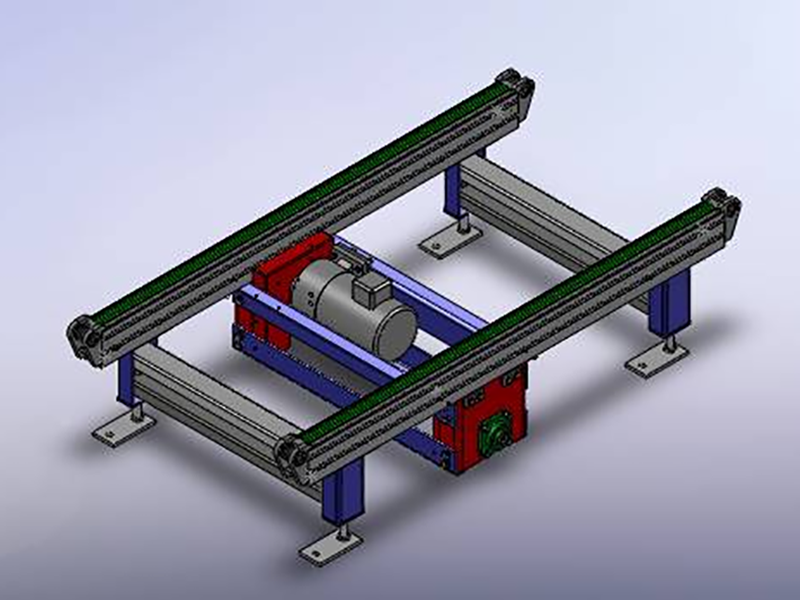

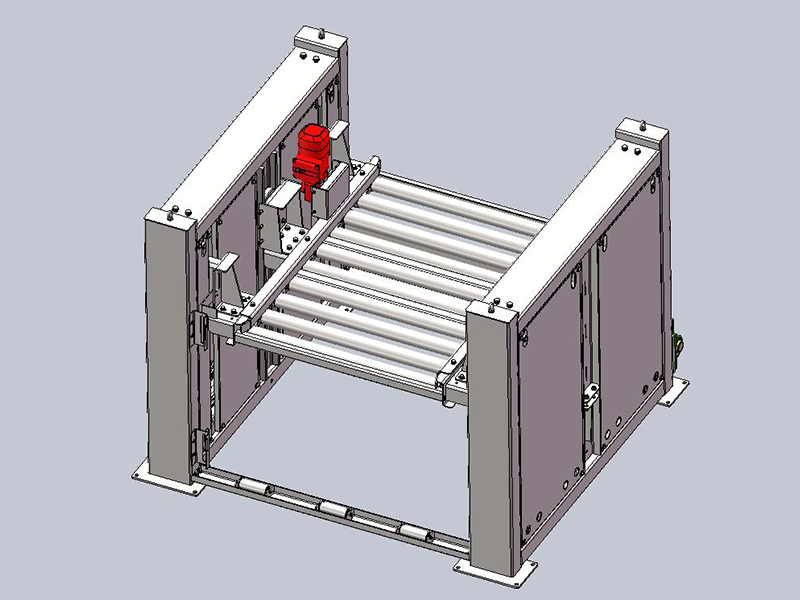

Jacking uye kutumira muchina

| project | Basic data | Remark |

| model | SX-YZJ-1.0T-6 0 0H | simbi yakagadzirwa |

| Motor reducer | SEW | |

| chimiro mhando | carbon steel bending | |

| control method | Manual/stand-alone/online/automatic control | |

| kuchengetedza matanho | Kupindirana kwemagetsi, madhiraivha ekudzivirira pamativi ese | |

| Standard | JB/T7013-93 | |

| payload | Max 1000KG | |

| kuongorora kutakura zvinhu | Photoelectric Sensors | Murwere/P+F |

| roller | 76 kaviri cheni roller | |

| Bearings uye dzimba | Kutakura: Harbin shaft; Kutakura chigaro: Fushan FSB | |

| kufambisa kumhanya | 12m/min | |

| Surface Kurapa uye Coating | Pickling, phosphating, kumwaya | |

| noise control | ≤73dB | |

| kupfeka kwepamusoro | komputa grey | Akabatanidzwa swatches |

Equipment structure

Equipment chimiro: Iyo roller yekufambisa muchina inoumbwa nekutakura zvikamu, nzira dzekusimudza, inotungamira zvikamu uye zvimwe zvikamu. Kuendesa kureba kwepamusoro kugadzirisa +25mm. Iyo yekusimudza meshini inotora musimboti weinjini-inotyairwa crank arm, uye mudziyo wekutyaira unoumbwa neyakavakwa-mukati yekudzikisa mota pakati, yekufambisa sprocket seti, chigaro chemota uye cheni yekumanikidza.

Kushanda musimboti: Kana iyo pallet yaendeswa kumidziyo nemutakuri anofananidzira, mota yejacking inomhanya, ichityaira cam mechanic yekusimudza pallet, uye mota yejacking inomira kana iri panzvimbo; mota yekufambisa inotanga, ichiendesa pallet kumidziyo yekumisa, uye Iyo mota inomira, mota yejacking inomhanya, uye cam mechanism inotyairwa kudzikisa michina, uye kana yave panzvimbo, mota yejacking inomira kuti ipedze kutenderera kwekushanda.

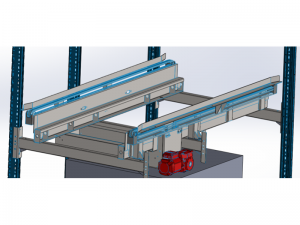

Transition conveyor

| 1) chirongwa | Basic data | Remark |

| model | SX-GDLTJ-1.0T-500H-1.6L | |

| Motor reducer | SEW | |

| chimiro mhando | Makumbo uye bent carbon steel | |

| control method | Manual/stand-alone/online/automatic control | |

| kuchengetedza matanho | Kupindirana kwemagetsi, madhiraivha ekudzivirira pamativi ese | |

| Standard | JB/T7013-93 | |

| payload | Max 1000KG | |

| kuongorora kutakura zvinhu | Photoelectric Sensors | Murwere/P+F |

| chain track | Low friction naironi track | |

| conveyor cheni | Donghua Chain | |

| Bearings uye dzimba | Kutakura: Harbin shaft, inotakura chigaro: Fukuyama FSB | |

| kufambisa kumhanya | 12m/min | |

| Surface Kurapa uye Coating | Pickling, phosphating, kumwaya | |

| noise control | ≤73dB | |

| kupfeka kwepamusoro | komputa grey | Akabatanidzwa swatches |

Equipment structure

Equipment chimiro: Chishandiso ichi chinoshandiswa pajoinhi pakati pehoist nesherufu, uye chinotakura chinoumbwa nefuremu, outrigger, uye drive unit. Iyo cheni yekutakura yakatwasuka kaviri-mutsara cheni ine pitch P = 15.875mm. Rutsigiro rwecheni rwakagadzirwa neakakwira molecular polyethylene (UHMW) ine self-lubricating maitiro. Welded makumbo, akabatana nesherufu muviri. Chishandiso chekutyaira chinoumbwa neyakavakirwa-mukati deceleration mota pakati, dhiraivha shaft gungano, yekufambisa sprocket seti, chigaro chemota uye cheni tensioning mudziyo, uye screw-mhando inogadzirisa tensioner pulley tension ketani inotakura.

Kushanda musimboti: Iyo mota inotyaira shaft yekutyaira kuburikidza neboka rekutapurirana, uye dhiraivha shaft inotyaira cheni yekufambisa kuti ione basa rekufambisa repallet.

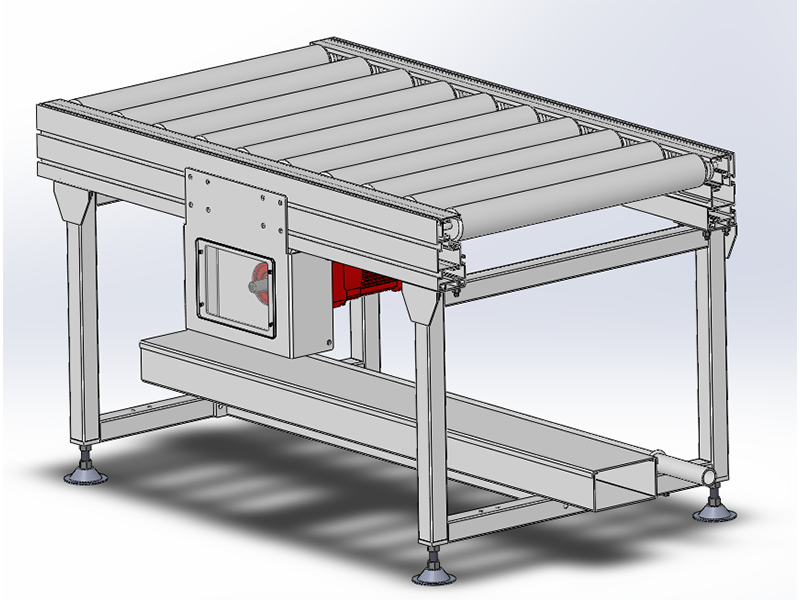

floor lift

| project | Basic data | Remark |

| model | LDTSJ-1.0T-700H | simbi yakagadzirwa |

| Motor reducer | SEW | |

| chimiro mhando | Column: kabhoni simbi kubhenda Kunze divi: simbi ndiro chisimbiso | |

| control method | Manual/stand-alone/online/automatic control | |

| kuchengetedza matanho | Magetsi anovharira, kudonha kusungwa mudziyo | |

| Standard | JB/T7013-93 | |

| payload | Max 1000KG | |

| kuongorora kutakura zvinhu | Photoelectric Sensors | Murwere/P+F |

| roller | 76 kaviri cheni roller | |

| kusimudza cheni | Donghua Chain | |

| kubereka | General bearings: Harbin shaft key bearings: NSK | |

| kumhanya kumhanya | Kufambisa kumhanya: 16m/min, kusimudza kumhanya: 6m/ min | |

| Surface Kurapa uye Coating | Pickling, phosphating, kumwaya | |

| noise control | ≤73dB | |

| kupfeka kwepamusoro | komputa grey | Akabatanidzwa swatches |

chimiro chikuru uye maitiro

Frame: 5mm carbon steel bent plate inoshandiswa sembiru, uye kunze yakavharwa nesimbi ndiro;

Kusimudza chikamu:

Iyo yekusimudza furemu inoiswa pamusoro peiyo hoist, furemu inogadzirwa nekabhoni simbi, uye iyo inosimudza mota inotyaira yekusimudza sprocket musangano kuti ushande kuburikidza neketani.

Loading platform:

Yakagadzirwa nekabhoni simbi. Iyo yekurodha chikuva yakashongedzerwa neyakajairwa conveyor.

kushanda musimboti:

Iyo mota yekusimudza inotyaira iyo yekurodha chikuva kuti ipedze basa rekusimudza; iyo conveyor papuratifomu yekurodha inogona kuita kuti zvinhu zvipinde uye kubuda musimudzwa zvakanaka.